Installation of ESP/CAPS¶

The link to the main Engineering Sketch Pad webiste is the following, ESP/CAPS.

A prebuilt distribution can be found in the PreBuilts/ folder. The following environment variables must be setup in the ~/.bashrc file.

The serveCSM command is useful in viewing the ESP/CAPS geometry from a .csm file. The alias csm

can be useful if one is running serveCSM command repeatedly (optional). Note the source * command

won't work until after the full install so you can ignore that if you source it immediately.

export ESP_ROOT=~/packages/ESP123/EngSketchPad

export PYTHONPATH=${PYTHONPATH}:$ESP_ROOT/pyESP

source $ESP_ROOT/ESPenv.sh

alias csm='$ESP_ROOT/bin/serveCSM'

The installation on a Linux machine proceeds as follows. Note if the ESP/OpenCASCADE version changes past ESP123, change the bashrc and install commands accordingly. The basic steps involve downloading the tar, unpacking it, and informing ESP/CAPS of the location of the OpenCASCADE directory (which comes with the prebuilt). Then, as the package is a prebuilt, we only need to make the tacsAIM directory which is not usually auto-built (don't need to make the rest of the source folder).

mkdir ~/packages/ && cd ~/packages/

wget https://acdl.mit.edu/ESP/PreBuilts/ESP123-linux-aarch64.tgz

tar -xvf *.tgz

cd ./ESP123/EngSketchPad/config/

./makeEnv ~/packages/ESP123/OpenCASCADE-7.7.0/

cd src/CAPS/aim/tacs/

make

The caps2tacs python module will not be imported unless ESP/CAPS is properly installed on your machine.

Intro¶

The differentiable CAD geometry in ESP/CAPS is defined in a CSM or Computational Solid Model file.

The user must write their own CSM file (see ESP/CAPS tutorials on their website) to define a structures geometry.

Important things to include in your CSM file are included below (for reference see the file examples/caps_wing/simple_naca_wing.csm).

Configuration parameters such as

cfgpmtr nribs 10which are integer variables usually fixed during optimization.Design parameters such as

despmtr span 10which are real number variables that can be tied to a TACS shape variable.capsGroupattributes define regions of the geometry with the same property cars, denotedcapsGroup $rib1, etc.We often use pattern statements to define these, and sometimes a user-defined primitive

udprim editAttr.

capsConstraintattributes define regions of the geometry intended to have the same structural constraints, e.g.capsConstraint fix.These constraints include Temperature and elastic constraints as of right now.

capsLoadattributes define regions of the geometry with the same fixed loads.This is useful in simple structural analyses. Note that aerodynamic loads cannot be setup this way (see the funtofem github for how to do this).

capsAIMattribute - this specifies for a body the analysis tools or AIMs using this CSM file.Note that we often add the

tacsAIM, egadsTessAIMhere for structural analyses.

Occasionally

capsMeshattribute - which can be used to set alternative auto-mesh settings on different sections of the geometry.

The main TacsModel object supervises the process of TACS analysis and geometry updates for optimization.

Caps2tacs supports MPI / parallel processing which is a feature not directly available in ESP/CAPS.

comm = MPI.COMM_WORLD

tacs_model = caps2tacs.TacsModel.build(csm_file="simple_naca_wing.csm", comm=comm)

Next, the user must specify the auto mesh generation settings for the structure geometry that will be used in the TACS analysis. The global mesh size depends on the scale of the model. You'll want to tune these auto-mesh hyperparameters by running a small analysis / using egadsAIM view routine until you get a quality mesh.

tacs_model.mesh_aim.set_mesh(

edge_pt_min=15,

edge_pt_max=20,

global_mesh_size=0.25,

max_surf_offset=0.01,

max_dihedral_angle=15,

).register_to(tacs_model)

There are certain objects that must be setup and registered to the tacs model before running a TACS analysis. If these are not correctly specified, then the tacs model will throw an error in the setup check phase.

- Material properties - you must setup one or more material objects for use in the element property definitions.

Available material types include Isotropic and Orthotropic (Anisotropic can be added directly through the underlying tacsAIM). Several common materials are saved as class methods such as aluminum, steel, titanium, carbon fiber.

- Element Properties - currently caps2tacs only supports shell elements for use in aerodynamic structures.

Element properties can be setup directly through a ShellProperty object or indirectly through the ThicknessVariable object. The names of shell properties or the thickness variables must be tied to a capsGroup setup in the CSM file.

- Constraints - elastic and thermal constraints are available in caps2tacs. Common instances are the

PinConstraintandTemperatureConstraint. The name/capsConstraint input to these constraint objects must match the

capsConstraintattributes in the CSM file.

- Constraints - elastic and thermal constraints are available in caps2tacs. Common instances are the

- Loads - for static problems

GridForceandPressureload objects are available whose names must match thecapsLoadattributes. Note that for aerodynamic structures only coupling with a CFD software such as through the

FUNtoFEM repo (see belowcan setup aerodynamic loads.

- Loads - for static problems

- Output Functionals for optimization - functionals such as

ksfailure,mass,temperature,compliance are available for use in structural optimizations.

- Output Functionals for optimization - functionals such as

Once all of the above structural analysis setup objects are provided, the TacsModel is ready for analysis. You can

then run the setup method which completes the setup phase. Then, the routines pre_analysis() generates a mesh,

the routine run_analysis runs the structural analysis and writes output solution files.

Finally the routine post_analysis() saves output functional values and derivatives using the adjoint method for optimization.

tacs_model.setup(include_aim=True)

tacs_model.pre_analysis()

tacs_model.run_analysis()

tacs_model.post_analysis()

Examples¶

The main caps2tacs example is in the directory ./examples/caps_wing/, with five analyses

on a coarse mesh of a symmetric NACA 0012 wing structure.

1. A steady analysis, using the EGADS AIM for meshing, with a vertical distributed load.

2. An unsteady analysis with a vertical distributed load varying sinusoidally in time.

3. A sizing optimization which finds the optimal panel thicknesses to hold fixed aero loads.

4. A sizing and shape optimization which optimizes the panel thicknesses and location of ribs

and spars inside the wing to hold fixed aero loads.

A steady analysis, using the AFLR AIM for meshing, with a vertical distributed load.

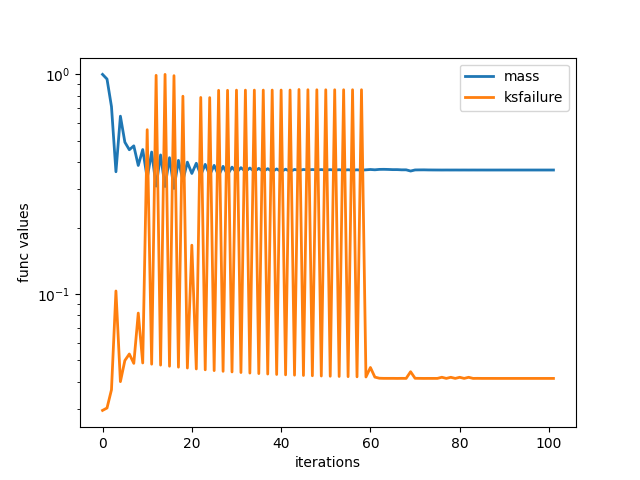

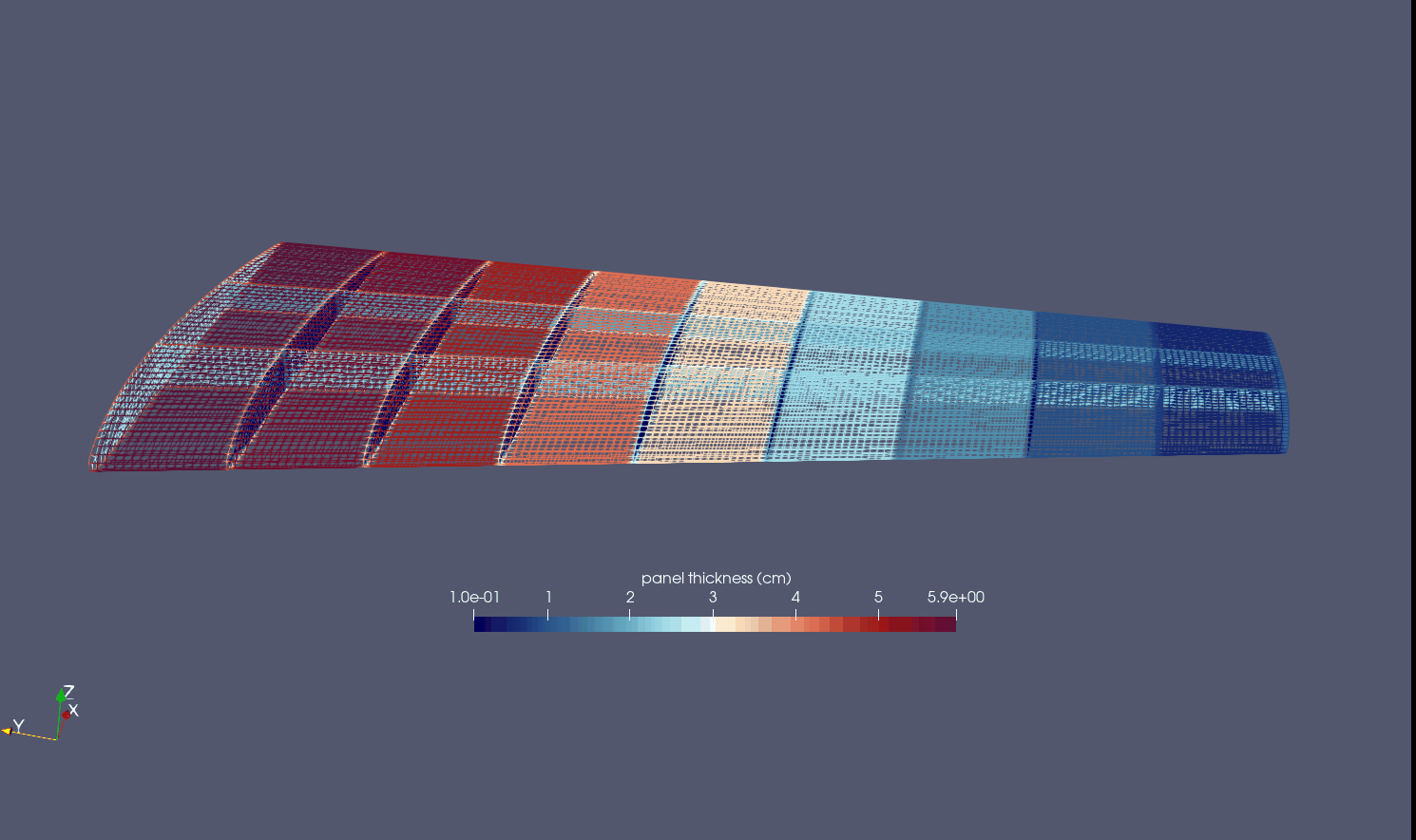

The sizing optimization shown below resulted in about a 40% drop in weight from the equal thickness design. Notice the optimal design has the largest panel thicknesses near the root as this is related to a beam bending problem with clamped root.

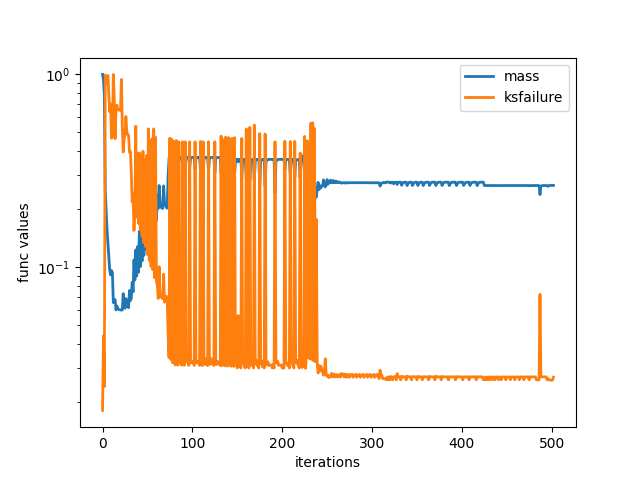

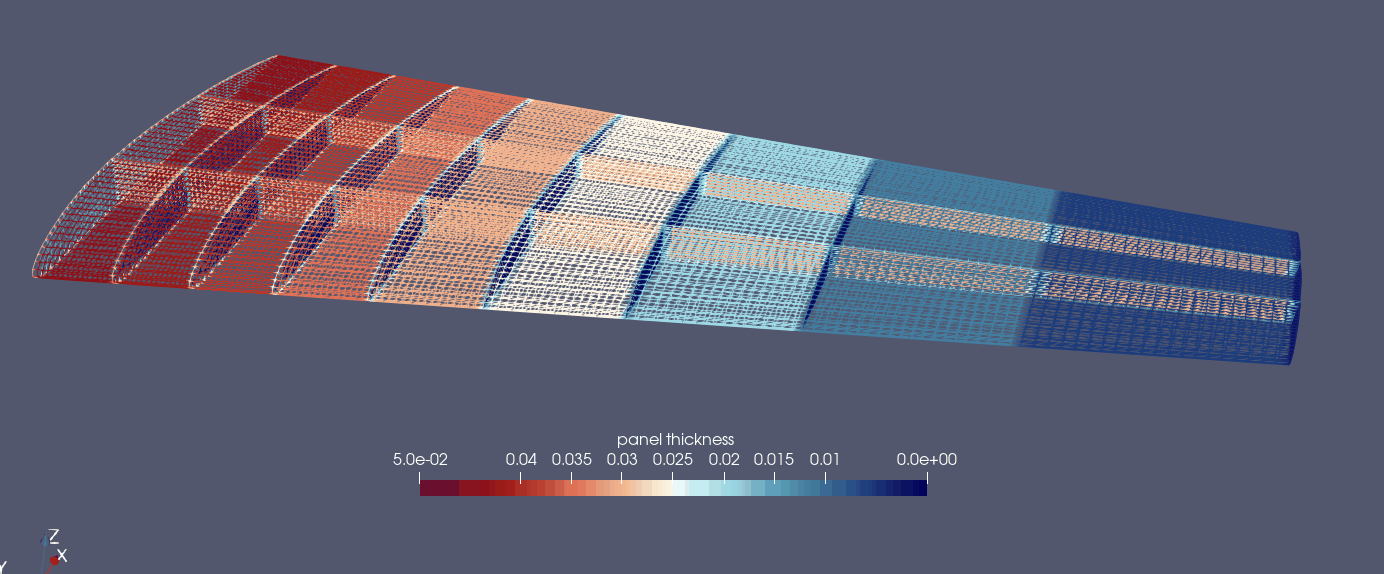

The optimization results for the sizing + shape optimization are shown below, which resulted in a 27% drop in weight from the optimal design of the sizing optimization. This suggests that the placement of ribs and spars is very important in designing a good wing structure. In this case, the spars move towards the leading edge with higher curvature.

For more examples using caps2tacs for thermoelastic analysis and involving CFD, please see the FUNtoFEM github.

Testing¶

Two different unittests can be used to verify your build of ESP/CAPS and TACS is working correctly. The unittests

are located at tests/integration_tests/test_caps_shape_derivatives.py and tests/integration_tests/test_caps_thick_derivatives.py.